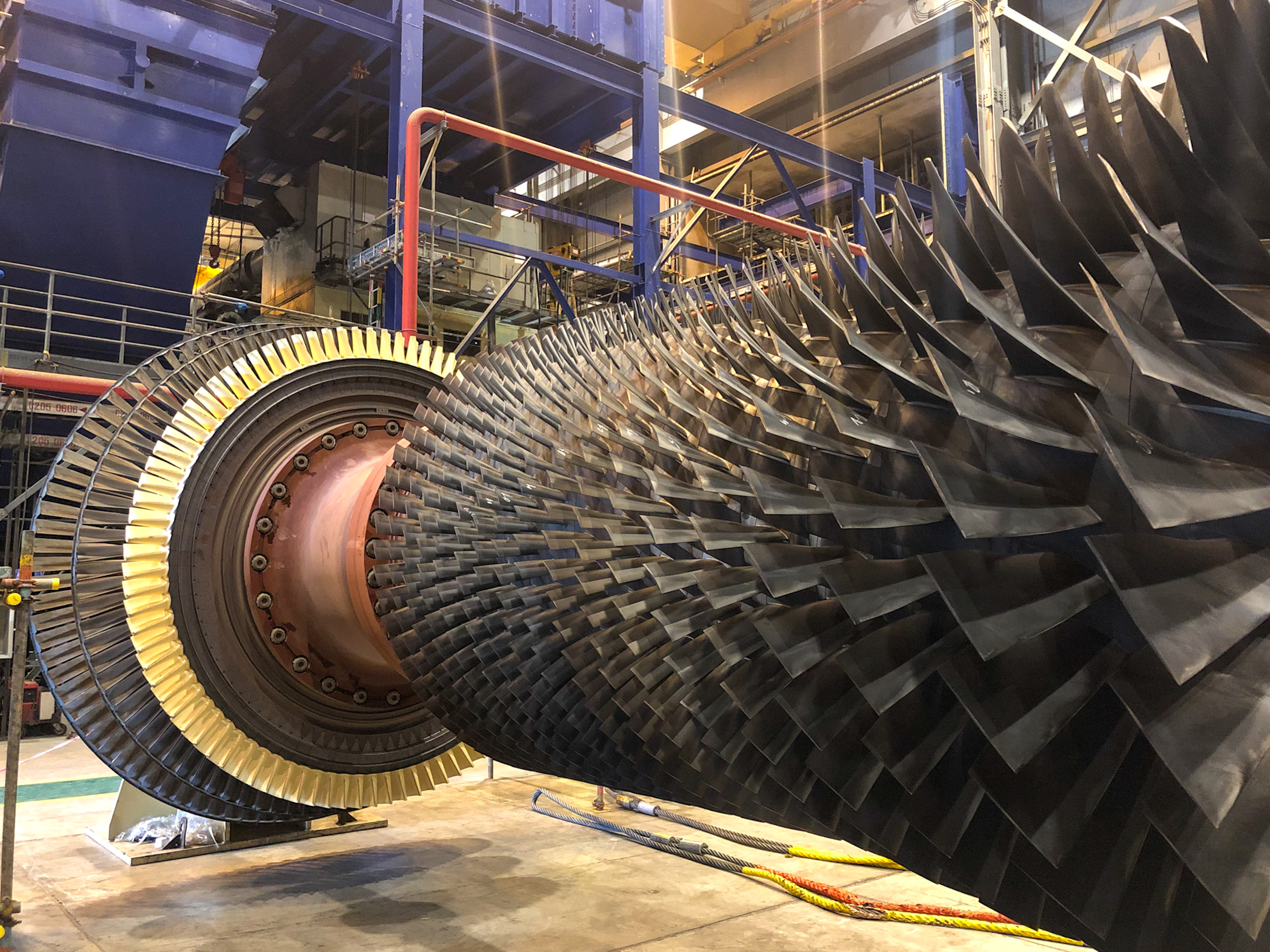

Turbine Blade Finishing

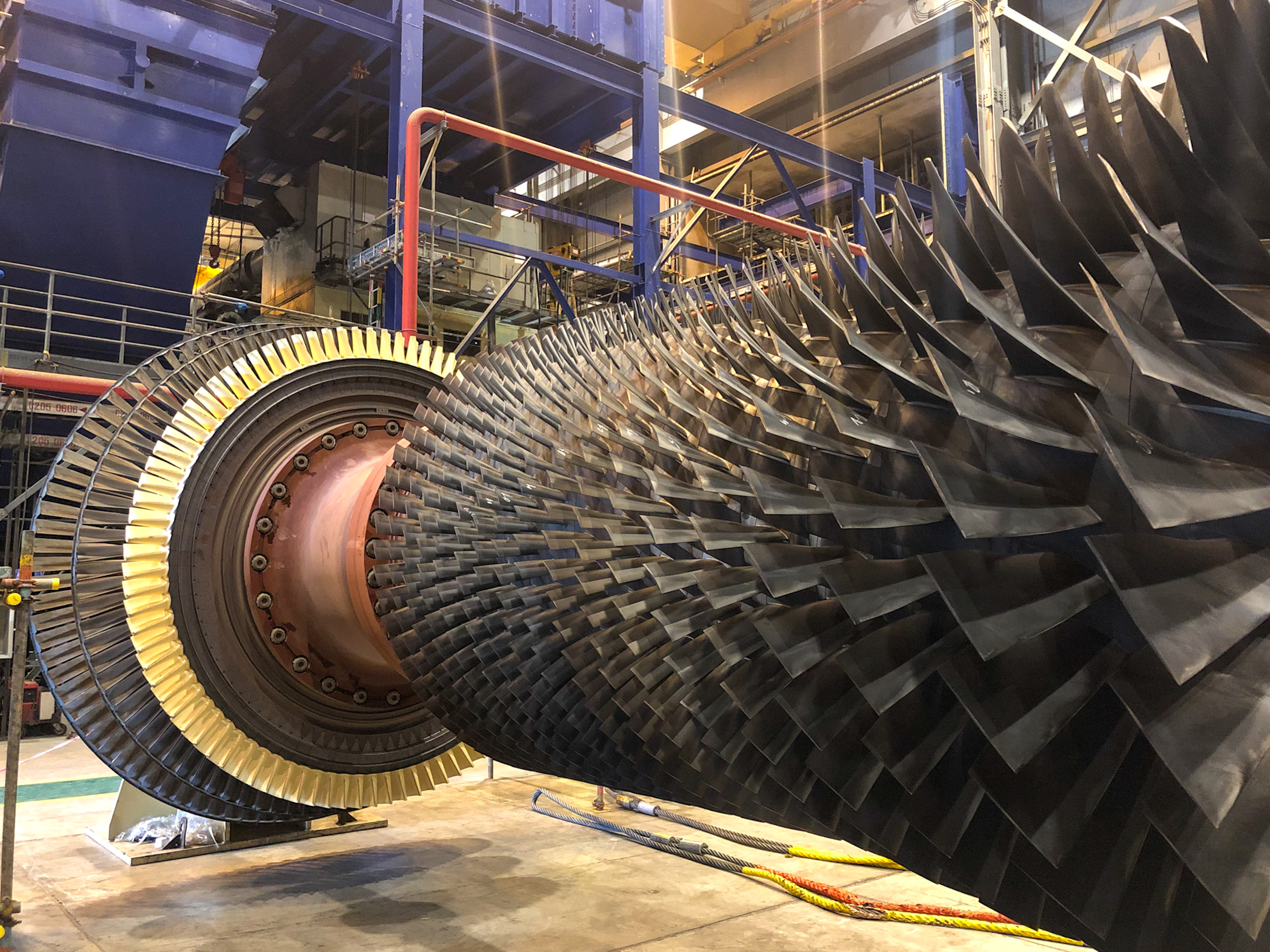

Thermal barrier coatings (TBC) are highly advanced materials systems applied to metallic surfaces, such as on gas turbine or aero-engine parts, operating at elevated temperatures, as a form of exhaust heat management. These coatings create a hard and tough-to-grind surface on turbine blades in different shapes and geometries, from small to quite large-sized parts. These 100 m to 2 mm thermal barrier coatings (TBC) can allow for higher operating temperatures while limiting the thermal exposure of structural components, extending part life by reducing oxidation and thermal fatigue. Due to increasing demand for higher engine performance (efficiency increases at higher temperatures), better durability/lifetime, and thinner coatings, there is an increasing trend in developing and applying TBCs.

These hard-to-grind materials require engineered flexible diamond abrasive solutions to keep productivity at the right pace, costs under control, and servicing within expectations.

INDUSTRY

Aerospace, Energy (Industrial Gas Turbines)

MAIN APPLICATIONS

KGS DIAMOND has developed a special range of super abrasives for grinding/finishing Thermal Barrier Coatings (TBCs) applications. Depending on the diamond grit size selected, these tools can grind a rough surface to the required finish, coping with complex geometries, contoured areas, and cleaning profiles. Suitable for a variety of hard-to-grind materials, including tungsten carbide and chrome carbide, thermal sprays Yttria-Stabilized Zirconia (YSZ) and alumina ceramics. It also easily removes coating oversprays and coatings prior to part refurbishment.

TYPE OF GRINDING MACHINES

Robots, power tools, pneumatic or electric.

PRODUCT OFFERING

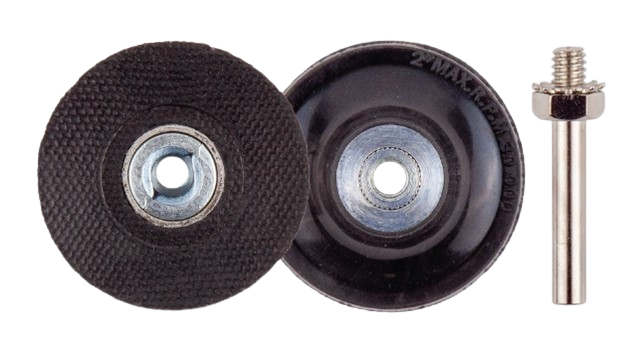

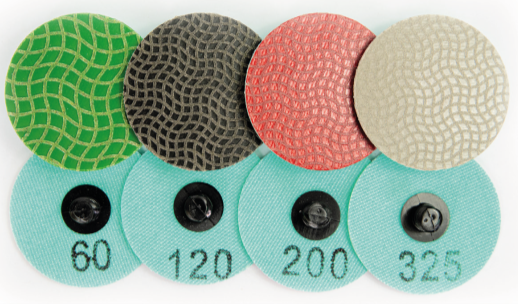

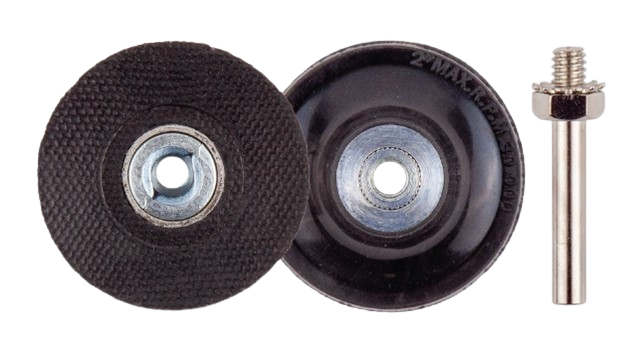

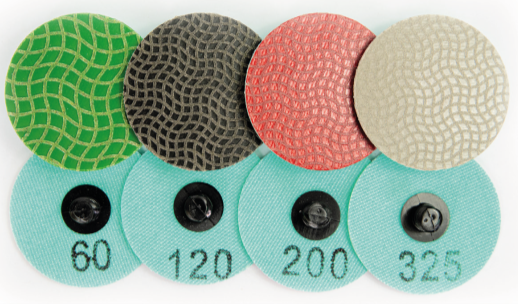

1. KGS Quadroflex™ K-Loc Diamond Disc

The Quadroflex™ K-Loc is a versatile and flexible diamond tool, rigid enough to remove material at a high rate and flexible enough to follow difficult geometries easily, making it ideal for hard-to-reach areas. KGS Quadroflex™ has a unique and continuous connected wave pattern for general purpose applications, which requires high stock removal. Excellent for cooler grinding and heavy grinding applications. A very strong no clogging pattern with an open structure. It ensures high stock removal and higher pressure per grit.

Common Sizes:

Ø25 mm | Ø38 mm | Ø50 mm | Ø75 mm

.png)

PRODUCT OVERVIEW

| Product |

Pattern |

Backer |

Flexibility |

Stretch |

Grit availability |

Wet/Dry |

|

KGS Quadroflex™ K-Loc Diamond Disc

|

Quadroflex™ |

BP - Heavy backing, Y-weight Wet & Dry poly-cotton, waterproof |

Medium |

Low |

60,120,200,325,400,800 |

Wet or Dry |

| KGS Quadroflex™ K-Loc Diamond Disc |

Quadroflex™ |

BYW4 - Strong heavy rigid backing, Y-weight polyester, waterproof |

Medium |

Low |

60,120,200,325,400,800 |

Wet or Dry |

Accessories: KGS K-Loc Back-up Pads:

Ø25 mm | Ø35 mm | Ø45 mm | Ø70mm

Contact us: sales@kgs.swiss.

Please refer to the page 'Locations' for all our locations, addresses and contact numbers.

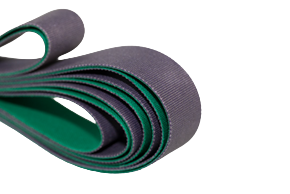

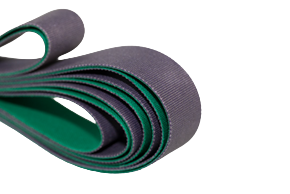

2. KGS Flexis® Flexible Diamond Belts

KGS Flexis® Large Flexible Diamond Belts are specially engineered for finishing ceramics, carbides and hard-coated materials. KGS Flexis® Belts are ideal for finishing and dimensioning flat and contoured surfaces, offering a perfect balance between cutting power and accuracy. It is mainly used for grinding thermal barrier coatings, finishing flat and contoured geometries, and cleaning profiles.

Common Sizes (in mm):

Minimum: 8 x 305 mm | Maximum: 300 x 5000 mm

PRODUCT OVERVIEW:

KGS Flexis® Diamond Belts for manual and stationary operations.

| Product |

Pattern |

Backer |

Flexibility |

Stretch |

Grit sizes |

Wet/Dry |

| KGS Flexis® Belts |

Flexis® |

BPG - Flexible polyester backing, XF- weight polyester, waterproof |

Medium |

Low |

120, 200, 320, 400, 800, 1500 |

Wet or mist of water. |

Contact us: sales@kgs.swiss.

Please refer to the page 'Locations' for all our locations, addresses and contact numbers.

Downloads

Download the KGS Quadroflex™ K-Loc Diamond Disc leaflet in PDF here.

Download the KGS Flexis® Belts leaflet in PDF here.

About KGS DIAMOND

KGS DIAMOND is the world's leading manufacturer of flexible diamond abrasives. KGS flexible diamond abrasive products satisfy the most demanding customer requirements for belts, discs, sheets and hand pads, bringing quality, productivity and innovation to the customer.

Founded in Switzerland in 1952, KGS has more than 20 sales and distribution offices in Europe, North America, the Middle East, Singapore, India, China and Australia, as well as six manufacturing sites located in Switzerland, The Netherlands, Hungary, Portugal, United Arab Emirates and India. Read more...

Follow us on social media:

- Facebook: https://www.facebook.com/KGSDiamondInternational/

- Instagram: https://www.instagram.com/kgsdiamond/

- LinkedIn: https://www.linkedin.com/company/kgs-diamond/

- YouTube: https://www.youtube.com/user/KGSDIAMONDWorldWide

Contact us:

KGS DIAMOND INTERNATIONAL

Industriestraat 2

8081 HG Elburg

THE NETHERLANDS

Tel. +31 525 683300

E-mail: sales@kgs.swiss

Or leave a message on our contact page. Please refer to the page 'Locations' for all our locations, addresses and contact numbers.

Go back to:

- Diamond Tools

- Superhard Coatings

.png)